Green Roof Polyurea Application in Qingdao Technological Uni

Construction Design,Application,Training,etc.

Outline

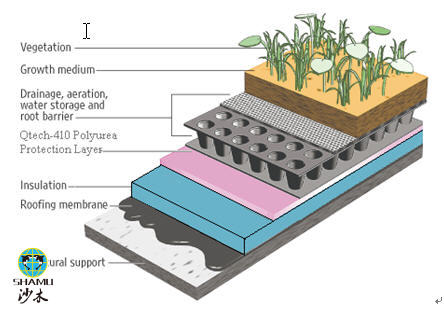

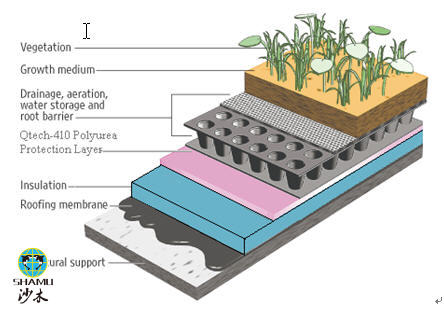

A green roof is a

roof of a

building that is partially or completely covered with vegetation and a growing medium, planted over a waterproofing membrane. It may also include additional layers such as a root barrier and drainage and irrigation systems.

In the past decade, Multiple-ply, single-ply membranes, PVC, EPDM rubber, TPO, Atactic Polypropylene (APP),Styrene-Butadiene-Styrene(SBS), Styrene Ethylene Butadiene Styrene (SEBS) modified bitumen waterproof membrane have been used by far to be the most traditional technology in the waterproofing industry. Most roof waterproofing membranes are made with these materials or include a reinforcement of non-woven polyester or glass mat. These traditional technologies have been proven to have many disadvantages:

· Seams, the most common place for a leak

· Low bonding adhesion

· Low resistance to acid soils and organic growth

· Unsuitable for blind side application

· Not good physicochemical properties

· Un-durability

· Application is sensitive to ambient temperature and humidity

As polyurea technology developed by our seasoned research and development team, its unique formulation and superior quality provide excellent properties, exceptional durability and resistance to severe weather conditions.

Polyurea applied to Green Roofing provides the following advantages:

? Seamless, flexible, slick and non-porous

? Excellent plant roots puncture resistant

? Fast cure, short down time, no sagging

? Excellent Physiochemical Properties

? Ultra High-Strength and High-Elongation

? Bondable to various kinds of substrates

? Ambient insensitive, good thermal stability

? 100% Solids, No VOC’s, Odorless, No Toxic Vapors

? Long term use and high durability

Project: No.2 laboratory building vegetated roofing in Qingdao Technological University

This project from polyurea formulation, construction design to installing is created by Qingdao Shamu International Trade CO., LTD. This vegetated roofing is used as an outdoor natural exposure testing field.

System:

Putty:

Qtech-112 repairing material

Primer:

Qtech-112 single component moisture curing polyurethane primer

Polyurea:

Qtech-410 Vegetated roofing Anti roots Puncture Polyurea Material

Construction design:

Area: 400 Sq. m

Application:

Surface Preparation

Area: 400 Sq. m

Application:

Surface Preparation

? Remove all grease, dirt, loose paint, oil, tar, glaze, laitance, efflorescence, loose mortar, cement, etc mechanically with grinding machine

? Hollow areas, bug holes, voids, honeycombs, fin form marks and all protrusions or rough edges are to be ground or stoned to provide a continuous surface of suitable texture for proper adhesion of polyurea

? Qtech-112 surface preparation system applying

Polyurea application

Polyurea application

The moisture and temperature of concrete surface and ambient humidity and temperature had tested prior to application. Nonworking surface was covered with plastic membrane to avoid contamination.

Insulation Drainage and Vegetation:

Insulation Drainage and Vegetation:

After polyurea cured, insulation layer, drainage layer and vegetation soil installed step by step strictly according construction design.

Training and outdoor exposure test field:

In order to emphasis the key of professional polyurea application of green roofing, Prof. Huang stands on the principle of combining theory with practice during the jobsite training, he taught each attendees one by one. It’s very professional, very practical and very hands-on.

This green roof is owned by Qingdao Technological University and it is used as an outdoor exposure test field for polyurea. It is definitely the biggest exposure test fields specialize in polyurea coating in the world. The total area is 400 Sq.m.